Surface treatment process

Surface treatment process

Dust is easy to adhere to the surface of silicone products. This problem can be effectively solved through appropriate post-treatment process. GR provides 2 surface treatment processes to customers.

1. Silicone oil coating:

Process flow: Mixing silicone oil – Feeding system (placement of products – cleaning) – coating – oven heating dry – Inspection – Next process

Advantages: 1. Its surface feels a little wet and soft smooth, giving people a better touch. 2. The surface has good anti-static effect and is not easy to adhere to dust.

Disadvantages: 1. The production process uses chemical solvents, which generate waste gas emissions. 2. The wear resistance is not very good, and easier to fall off after half a year service.

2. UV surface modification:

Process flow: Place the product-UV irradiation/baking-inspection-next process

Advantages:

1. The surface feels smooth.

2. The surface has good anti-static effect and is not easy to adhere to dust.

3. Good wear resistance, basically no wear and tear off, long service life.

4. The production process is environmentally friendly and will not produce waste gas emissions.

Disadvantages: The touch feeling is slightly dry and worse than the silicone oil coating.

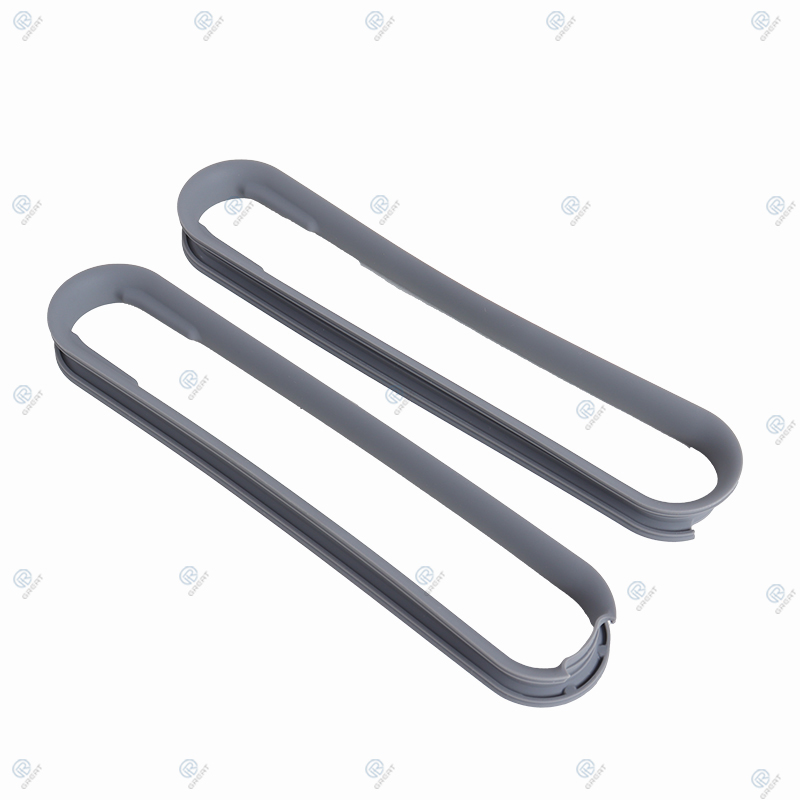

Related products

Get A Free Quote

ShenZhen Great Technoloy Co., Ltd. was founded in 2005, specializing in the research and development, production and sales of silicone and rubber products.